Optical brightener is the product with the best heat resistance among all optical brightener products. It not only has a high decomposition temperature, good whiteness, and a small amount (generally 25~300 mg/kg), but it also has good properties with additives in plastic .It is mainly used for the whitening of polyester resin, polyester fiber, ordinary plastics and engineering plastics. The three process routes reported in this article have been tested in the laboratory and can be used for the production of products with different quality requirements.

Today we will show you how to make optical brightener ,there are 3 ways to produce optical brightener OB-1

Optical brightener OB-1 is the product with the best heat resistance among all optical brightener products. It not only has a high decomposition temperature, good whiteness, and a small amount (generally 25~300 mg/kg), but it also has good properties with additives in plastic .It is mainly used for the whitening of polyester resin, polyester fiber, ordinary plastics and engineering plastics. The three process routes reported in this article have been tested in the laboratory and can be used for the production of products with different quality requirements.

Today we will show you how to make optical brightener OB-1 ,there are 3 ways to produce optical brightener OB-1

1 Sulfur process make optical brightener OB-1

Raw materials: sulfur powder, 4-methylphenylbenzoxazole, xylene, DMF (N,N-dimethylformamide), NP (N-methylpyrrolidone), all industrial products.

Synthesis:The synthesis of the process includes three parts: vulcanization, desulfurization, and refining.

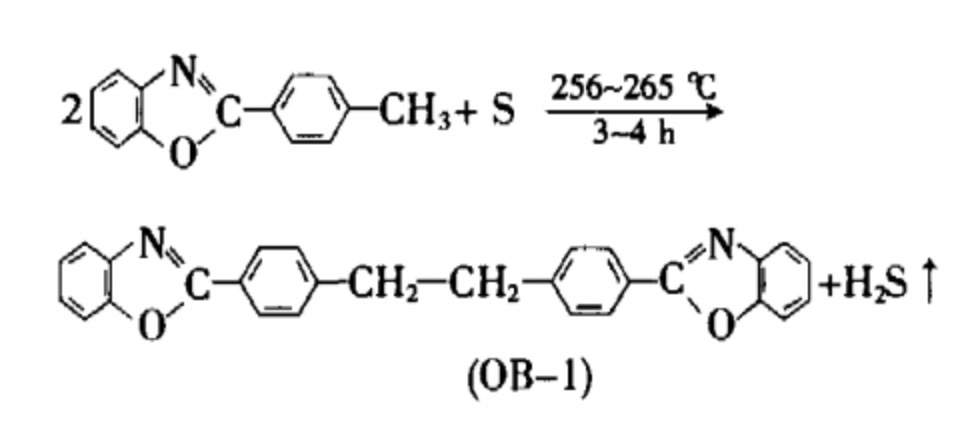

(1) Vulcanization

Put 4-methylphenylbenzoxazole and sulfur alternately into the vulcanizing kettle at a mass ratio of 1:2~2.5, and heat to 150℃, start stirring, continue heating to 240℃, turn on the H2S absorption device, at 255~265 The reaction temperature is within the range of ℃ for 3 to 4 hours, the temperature is cooled to 160 ℃ at the end of the reaction, a certain amount of xylene is slowly added dropwise, and the material liquid is put into the desulfurization kettle at 120 ℃.

(2) Desulfurization

Heat the liquid in the desulfurization kettle to reflux for 1 hour, and filter while it is hot when the temperature is lowered to 100°C; put the filter cake into the desulfurization kettle, add a certain amount of xylene and heat to reflux for 1 hour, cool to 100°C and filter while it is hot, repeat 3 ~4 times, the last time it was spin-dried with a centrifuge to obtain crude optical brightener OB-1.

(3) Refining According to requirements, the crude product can be refined with DMF or NP.

The production method is simple in process, but has the disadvantages of low yield (50%), large pollution, and high temperature required for production. At present, there are not many domestic manufacturers using this method, but the quality of the products produced by this method is relatively good, basically comparable to those imported from abroad. It should be noted in production that after the vulcanization, the temperature should be cooled quickly, and the purity of the sulfur powder should be high, and the water content (mass fraction) must be below 0.5%. It is best to use sublimated sulfur powder.

2 Sodium tert-butoxide method make optical brightener OB-1

Raw material:Sodium amide, tert-butanol, p-chloromethylphenyl benzoxazole, toluene, DMF, NP are all industrial products.

Synthesis:The synthesis of the process includes three steps of catalyst preparation, synthesis and refining.

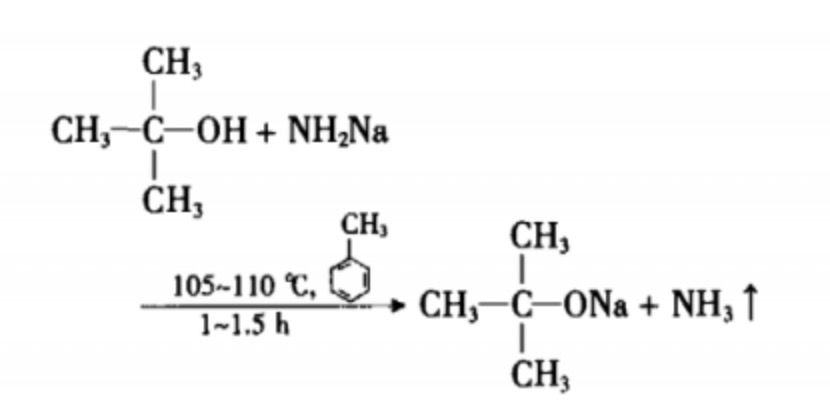

(1) Preparation of sodium tert-butoxide

The synthesis reaction formula of sodium tert-butoxide is as follows:

Add toluene, sodium amide, and tert-butanol into the catalytic kettle in a certain proportion in the order of the front and back. After sealing, turn on the stirring and heating, react at 105~110℃ for 1~1.5h, then cool to below 20℃, add a small amount DMF diluted for use

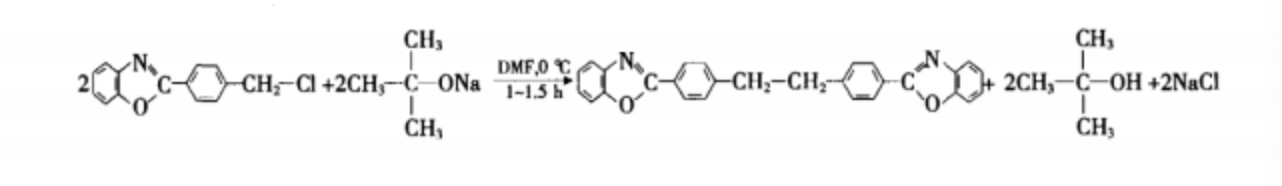

(2) Synthesis:The reaction formula for synthesizing OB-1 by sodium tert-butoxide method is:

Put the p-chloromethyl phenyl benzoxazole and DMF into the synthesis kettle in a certain ratio. When the temperature drops below 0℃, quickly add the prepared sodium tert-butoxide, and fully react for 1~1.5h. , Add a small amount of glacial acetic acid to adjust the pH to about 7, press filter, filter cake, that is, crude optical brightener OB-1.

(3) Refined

According to the need for purity. Recrystallize with DMF or NP. The production process is simple, the raw materials are easily available, the yield is high (79%), and it is pollution-free. It is an environmentally friendly process. At present, 4 to 5 domestic manufacturers adopt this process, and the OB-1 cis structure produced is more than the trans structure. Structure, poor fluorescence, good whitening effect, suitable for whitening common plastics and engineering plastics. In the synthesis, the quality of sodium tert-butoxide directly affects the yield of the product, the highest temperature during the synthesis reaction directly affects the appearance, color and fluorescence intensity of the optical brightener OB-1 product, the entire reaction of the process and the main raw materials used for water content The requirements are particularly strict and must be less than 0.5%.

3 Oxazole aldehyde method make optical brightener OB-1

Synthesis process: The synthesis process of OB-1 produced by oxazole aldehyde method mainly includes three steps of esterification, condensation and recrystallization.

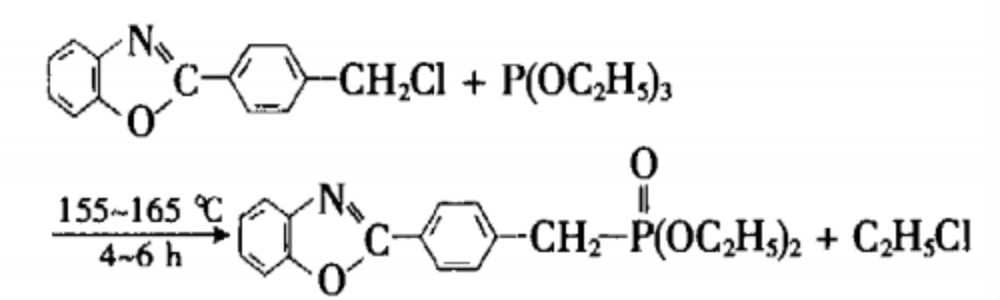

(1) Esterification:

Put the p-chloromethyl phenyl benzoxazole and triethyl phosphite into the esterification kettle at a ratio of 1:1.2, and then heat up to 155~160°C for 4~6 hours. The excess triethyl phosphite was distilled off under reduced pressure to obtain a light yellow ester compound. The reaction formula is:

(2) Condensation

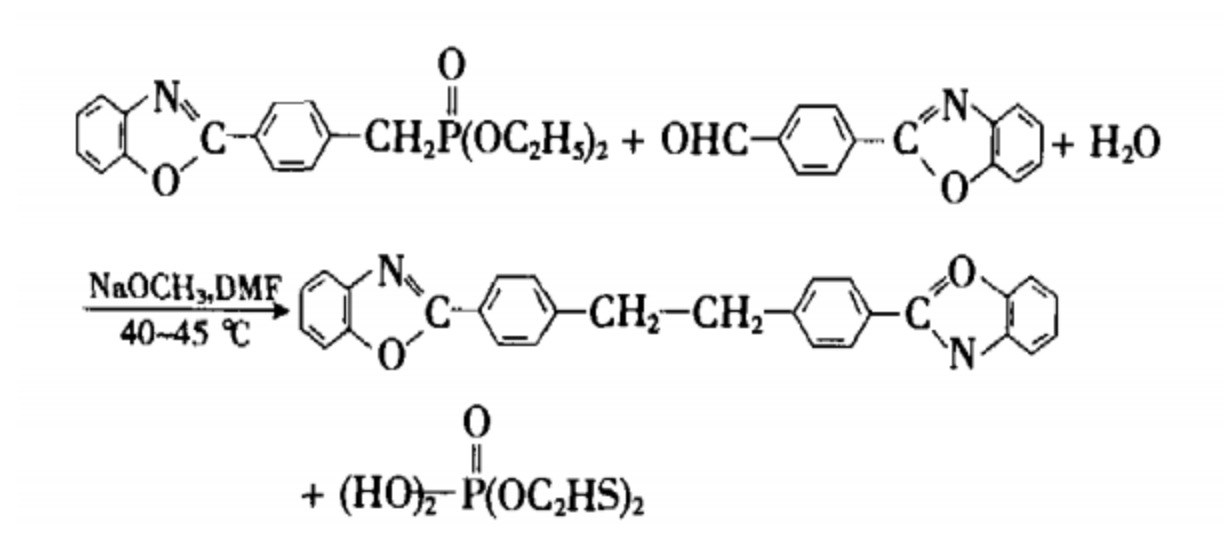

The reaction formula of condensation is:

Weigh the oxazole aldehyde in the same amount as the p-chloromethylphenyl benzoxazole, add it to the esterified product, then add an appropriate amount of DMF, heat up to the material completely dissolved, and then cool down at 40~45℃ Add a solution of sodium methoxide (29%) dropwise. After the dropwise addition, the temperature is raised to 60°C, reacted for 2~3h, cooled and filtered under pressure to obtain crude optical brightener OB-1. The process is simple, pollution-free, and has a high yield (81%). It is the process adopted by most domestic manufacturers. The OB-1 trans structure produced by this process is more than the cis structure, the fluorescence is good, and the product has a beautiful appearance. When used for polyester chemical fiber and polyester polyester, the use effect is better than the optical brightener OB-1 produced by the above two processes.

Shandong Raytop Chemical Co.,Ltd established in 2006.We are optical brightener manfuacturers and factory. Now days we has three production bases,with total area of 120,000 square meters, 6 workshops and more than 260 employees. We are the most professional optical brightener suppliers and manufacturers in China. We have a optical brightener factory,special advantage products optical brightener for plastic, discrete optical brightens, optical brightener in textures, optical brightener in paper and masterbatch and so on.

https://www.raytopoba.com/How-to-make-optical-brightener-_95.html